Storing and conveying

At CK Teknik, we specialize in custom-made storage and transport solutions, which means that all of our machines and products can be adapted to fit your production needs, whether you require a specific size silo.

More information is available about each product and machine in the downloadable PDF.

SI78 – Single silos

Our SI78 silos are made of antistatic woven fabric, an essential feature in the EPS/EPP production, and the silo frames of galvanized steel. The entire silo is fully demountable.

The size and design of the silo as well as the position and design of the inlet and outlet are all according to customer specifications. The silos are prepared for level detectors as standard at the top and bottom, and as an option the silos can be equipped with a complete weighing system for weight measurements.

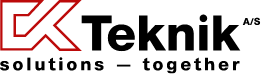

SI75 – Silo systems with controls

The silos are made of antistatic woven fabric, an essential feature in the EPS/EPP production, and the silo frames are made of galvanized steel. The size and design of the silos as well as the position and design of the inlet and outlet are all according to customer specifications. The silos are prepared for level detectors as standard at the top and bottom.

With the system, you get:

- A complete filling system with manual/automatic silo selection, blowers, etc.

- Emptying lines with distribution boxes, with the option to add more connections to each silo.

- Ladder and walkways for each access to technical components.

- Control of automatic filling/emptying.

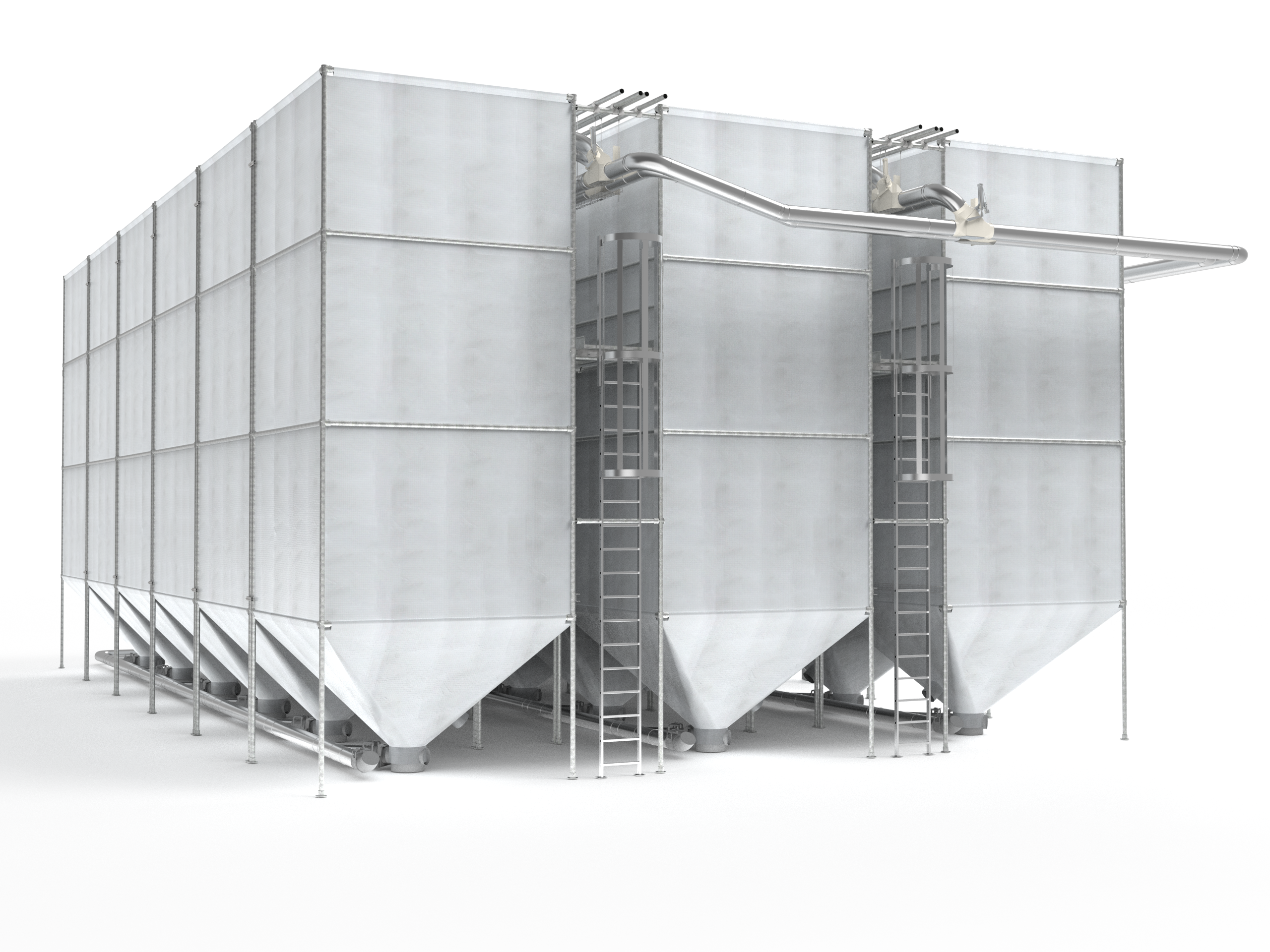

SK43 – Distribution boxes

Our SK43 distribution boxes range from 1 to 20 outlets and come with adjustable 2” ball valves for regulating the quantity of material. The inlet is delivered with a OK200 flange with quick coupler.

All outlets are fitted with hose connectors for a Ø50 hose, but other solutions can also be offered on request. And the outlets are fitted with 1” valves for regulating the amount of transport air.

Other solutions are also available on request.

SK45 – Distribution units

Our SK45 units come with outlets in large diameters (standard: Ø160, Ø200, Ø250, Ø300) and quick couplings.

The units are available with different options for opening and controlling the material quantities (manual or automatic) and are produced in galvanized steel.

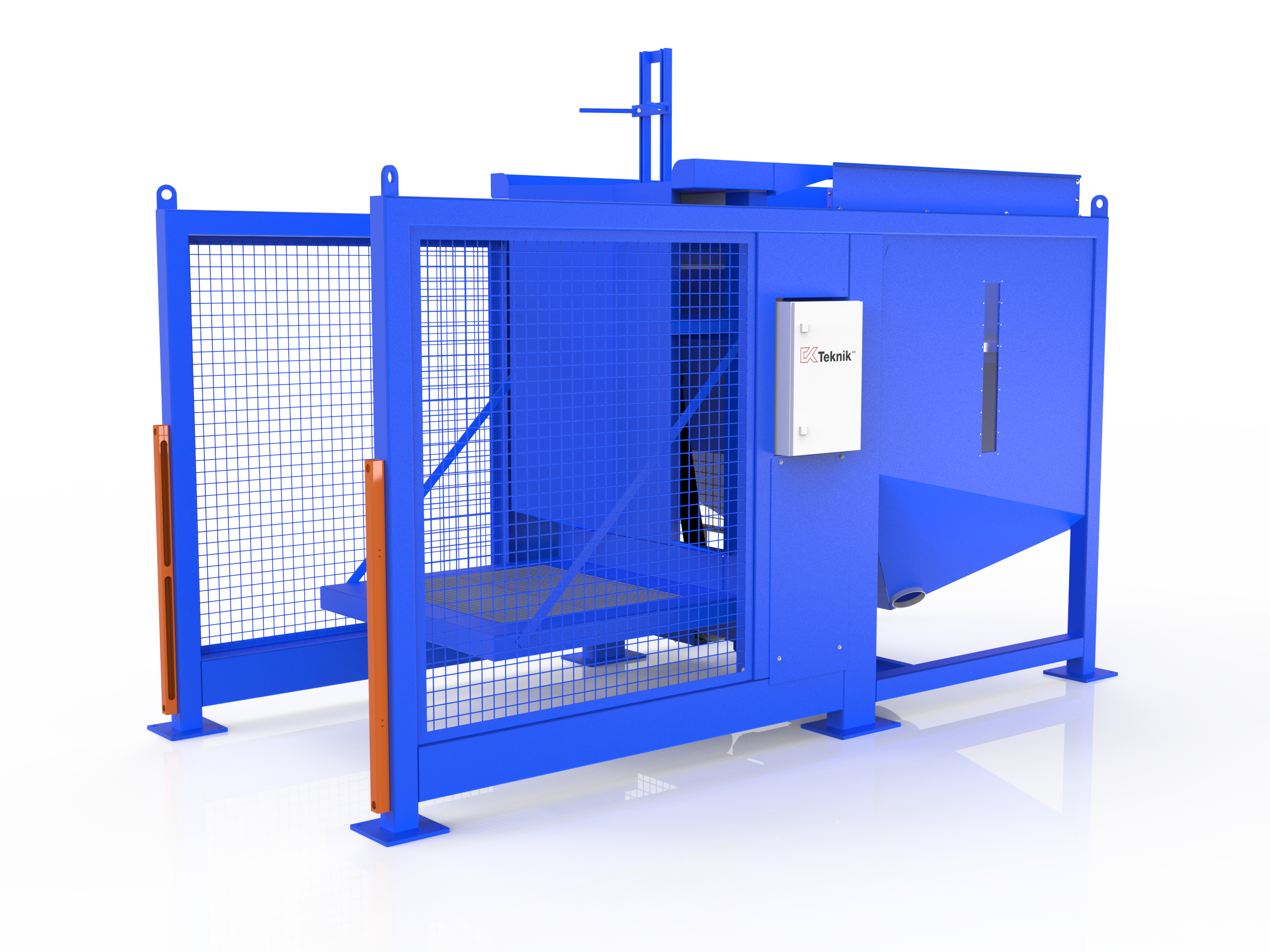

RT32 – Raw material tilting station

The RT32 station is designed to empty octabins containing raw material. This is done by placing the octabin in the cradle of the machine with a forklift, whereupon it is emptied, with the help of a hydraulic cylinder, into a hopper. From there, the raw material is transported to the pre-expander via augers.