Handling

We have handling machines for every aspect of the production line, from crate removal machines to absorbent pad feeders. But if you can’t find the machine you are requiring, please don’t hesitate to contact us. We specialize in custom-made handling machines and would be happy to assist you.

More information is available about each product and machine in the downloadable PDF.

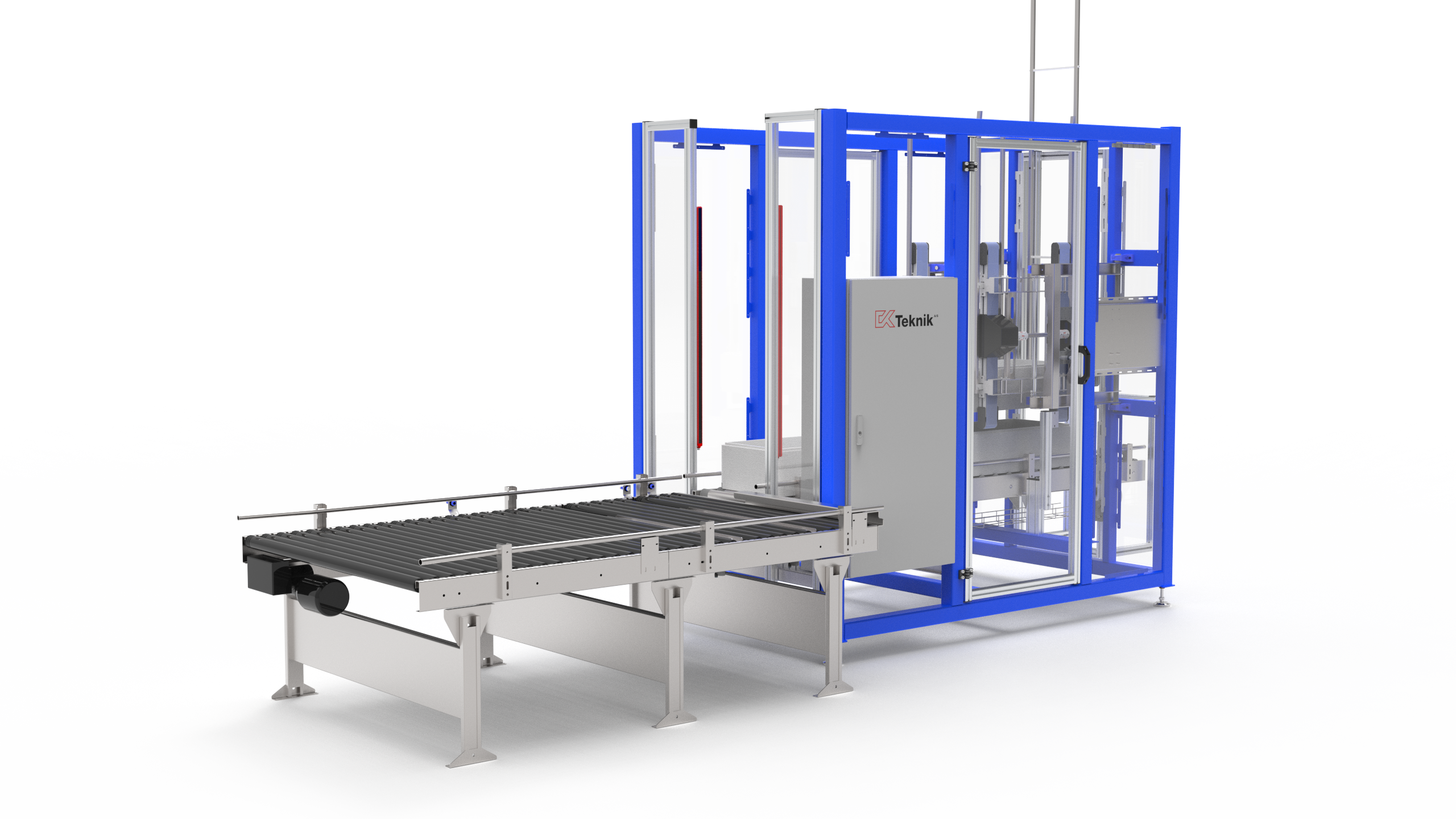

FS20 – Stacker for boxes

The FS20 stacker is designed to stack various stacks of boxes.

The stacker can be adjusted to stack different amounts of boxes in each stack.

Alternatively, roller conveyors can be installed to transport the stacks to trucks or the warehouse.

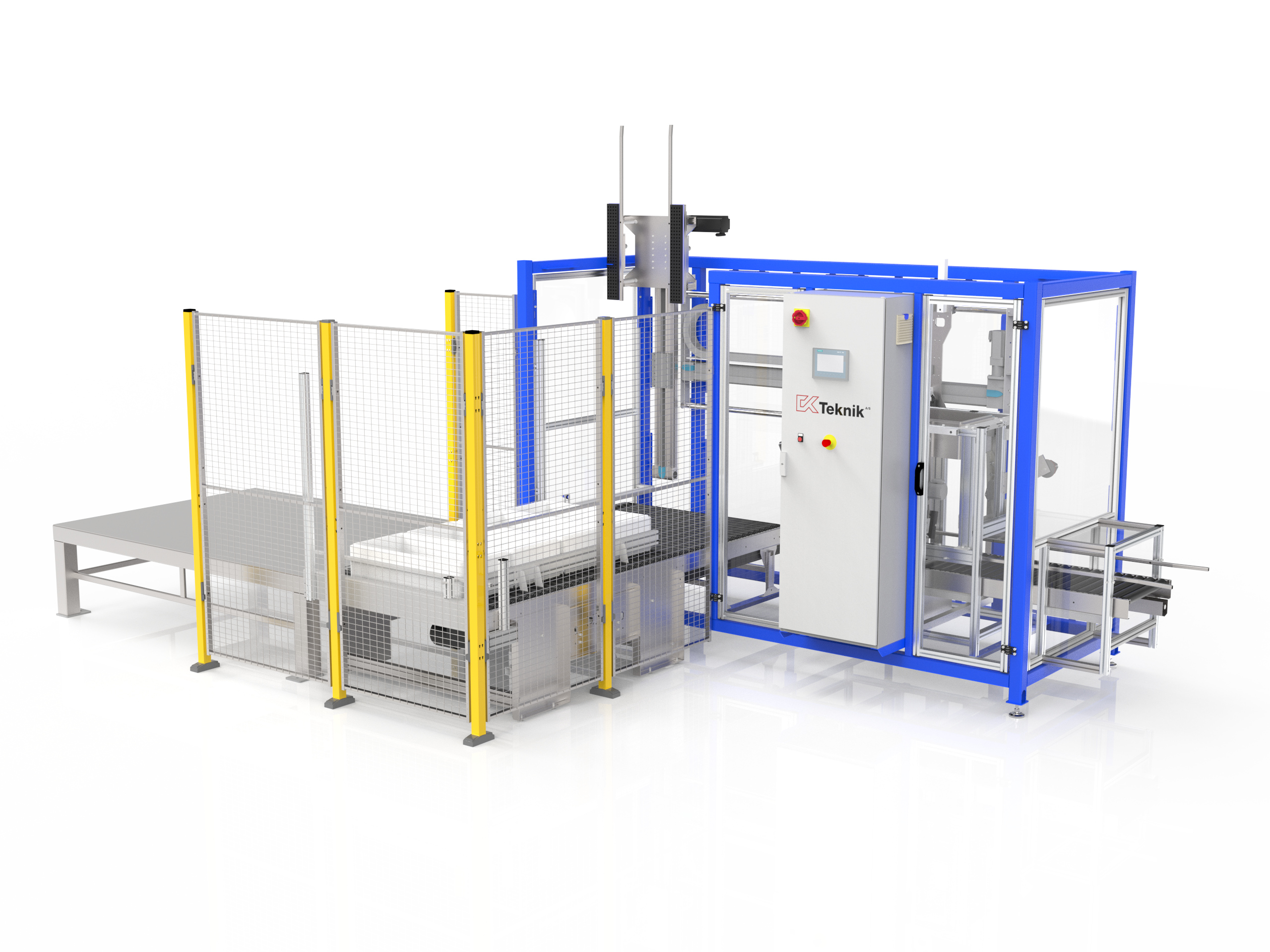

FS21 – Stacker for boxes

The stacker is designed for stacking and taping various stacks of boxes.

The stacker can be adjusted to stack different amounts of boxes in each stack (Min. 4 Boxes)

The numbers of final stack rows, is adjustable according to customer requirement.

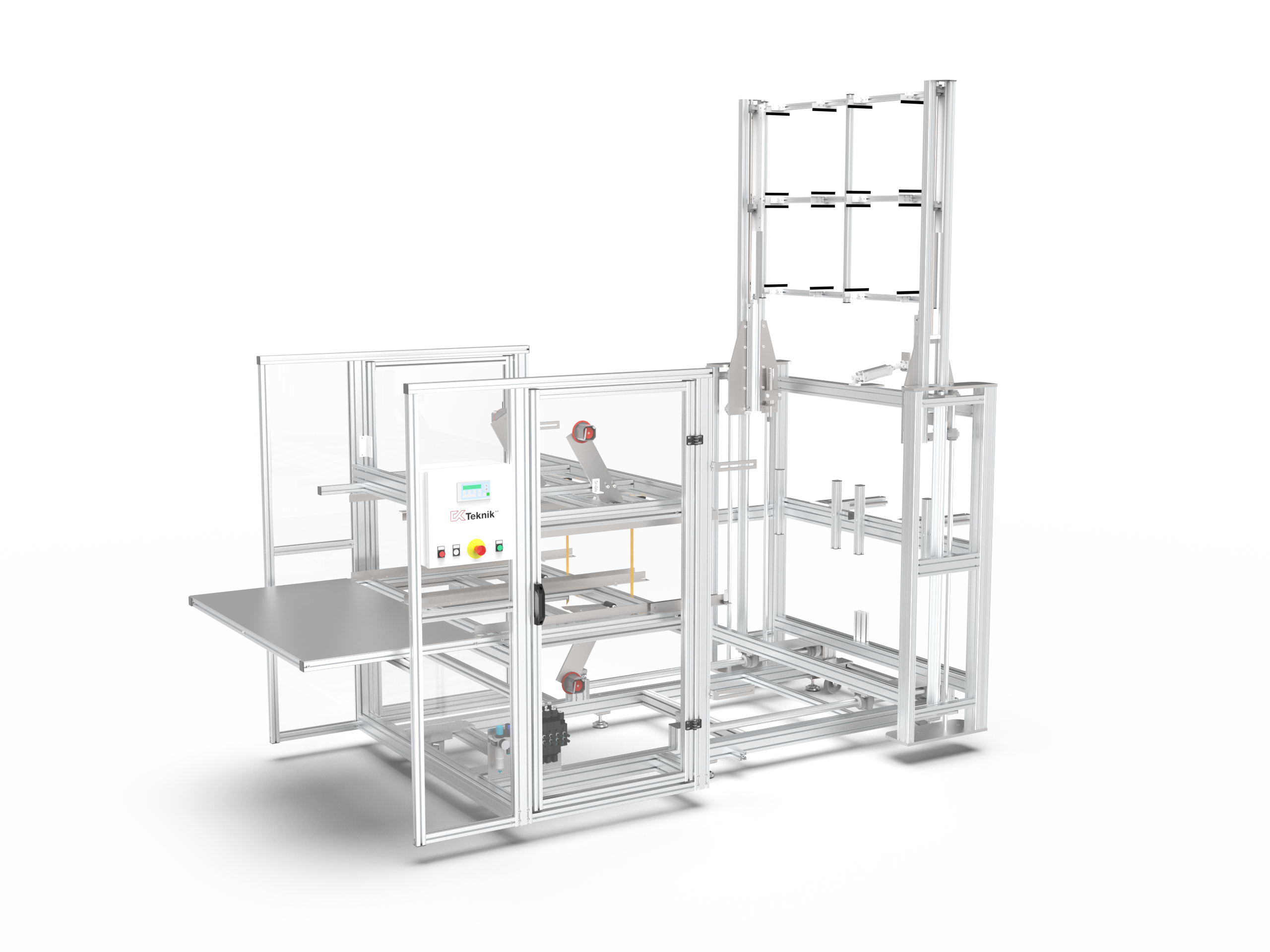

FS22 – Stacker for boxes

The stacker is designed for stacking and taping various stacks of boxes.

The stacker can be adjusted to stack different amounts of boxes in each stack (Min. 4 Boxes)

SU07 – Removal device for fish crate lids

The SU07 removal device is designed to stack and tape lids for fish crates and can be adjusted (in intervals of 3 lids) to stack the desired number of lids. The device is easily positioned under the molding machine by means of guide pins, whilst maintaining easy access to the molding machine.

The device is easily disconnected and moved when required.

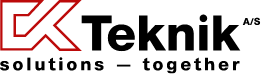

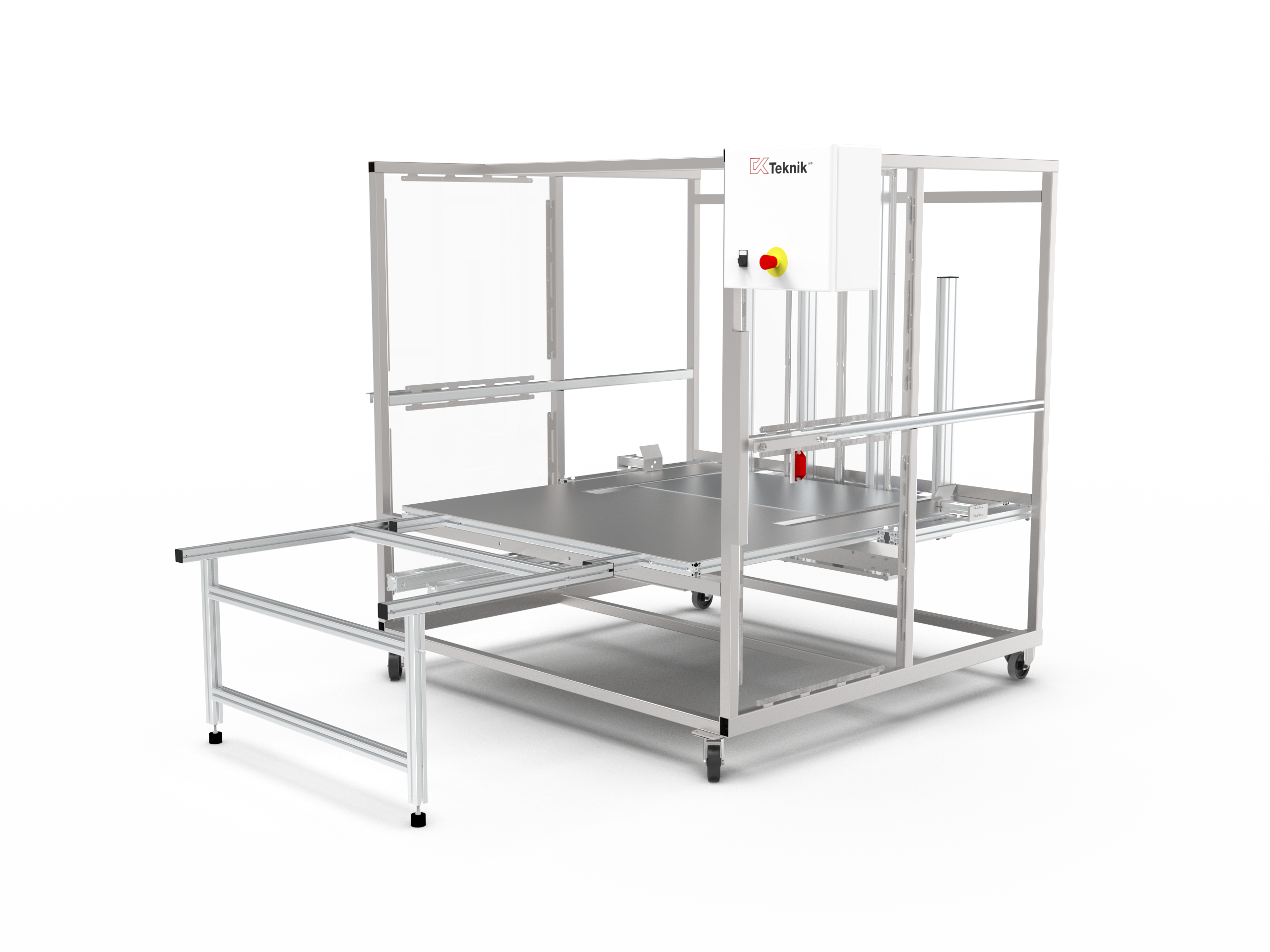

SU05 – Removal device for fish crates

The SU05 removal device is designed to either receive the falling crates directly from the mold or, for a more careful handling, grab the crates straight out of the mold.

The device can be customized according to customer specifications and can be delivered with either a table in front of the machine or with a conveyor belt in front or behind the machine.

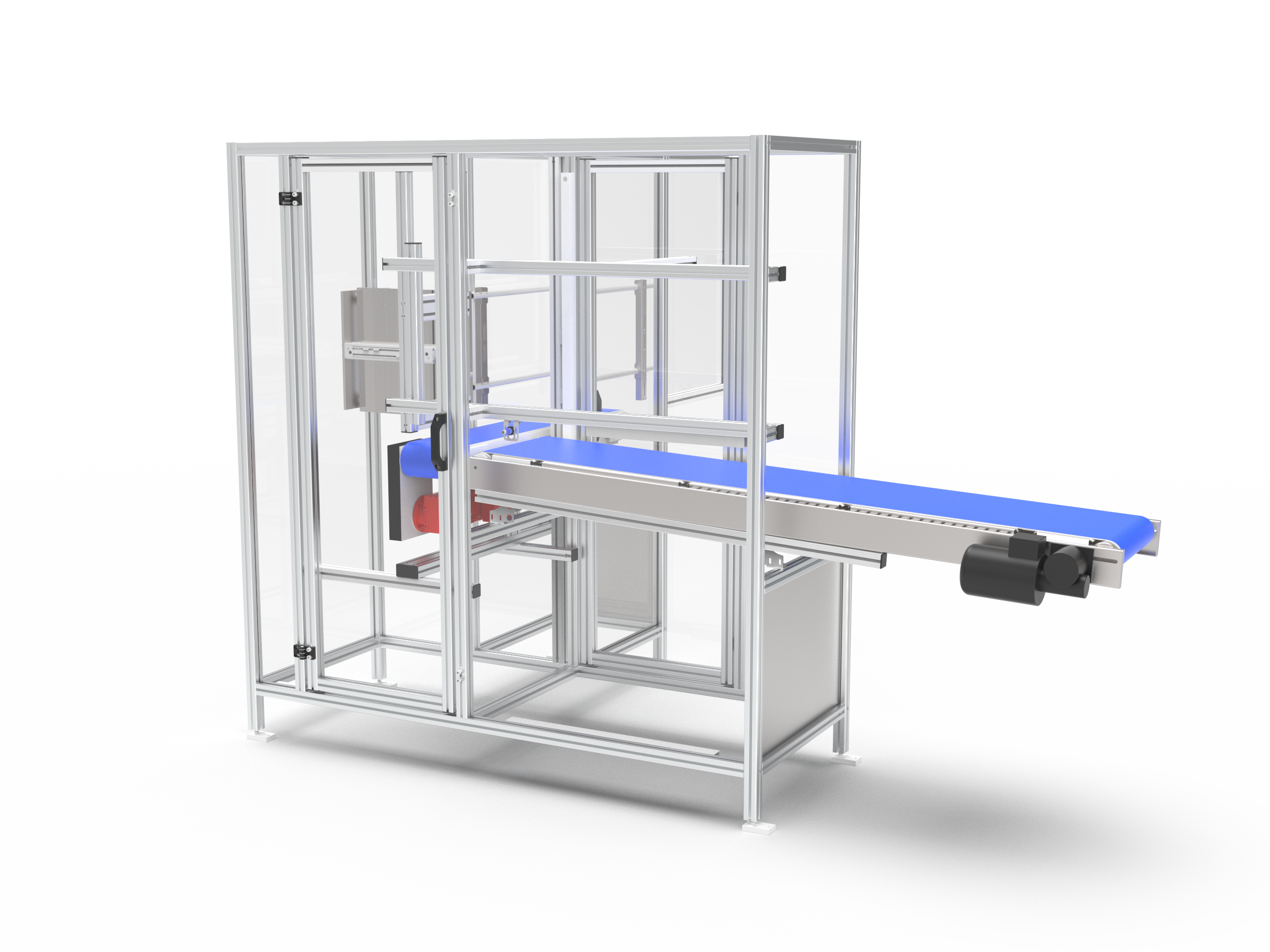

AI38 – Absorbent pads feeder

The AI38 machine is designed for the placement of absorbent pads in fish crates and is usually positioned before a stacking or taping machine.

In order to run, absorbent pads are stocked up in the machine beforehand. This allows for the machine to start automatically and feed the crate through the feeder via conveyor belts.

If requested, the machine can be delivered with an automated gluing system, which sprays glue from 2 nozzles into the box to keep the pads in place.

BU15 – Removal device for blocks

The BU15 removal device is designed to receive the falling blocks directly from the mold.

The machine is designed according to customer specifications and can be delivered with either a table in front of the machine or with a conveyor belt in front or behind the machine.

SD18 – De-stacker for boxes

The De-stacker is designed for De-stacking various stacks of boxes.

After the De-stacker the boxes are transportet one by one for further use in the automated process.

FV11 – Boxturner

The box turner is used when it is necessary to change director or orientation of boxes and can be designed to accommodate all directions of travel.

The machine is easily integrated into the existing conveyor system.